I was recently thinking how technology has changed so much just in my lifetime. Music is a great example of an ever-evolving technology. I remember buying records as a kid, then cassettes and then CDs. This evolved into downloading music to my computer/device. Now I subscribe to a steaming service and have every album I ever wanted on my phone. Similar major changes are also reflected in my chosen fields of HVAC and energy management systems (EMS). The EMS has reinvented itself again and again over the years. It’s not your father’s energy management system anymore.

Current EMS are so powerful and can complete so many tasks in seconds compared to the original types of HVAC control systems. It’s like playing music from an 8-track tape and comparing it to a streaming music service with endless choices.

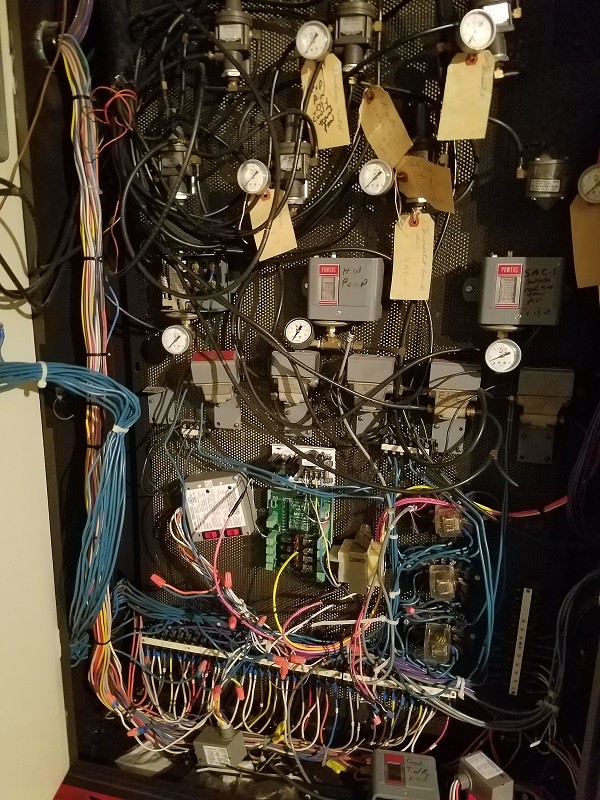

The HVAC controls systems in the 1980s when I got my start in this industry were very simple. There were basically two common types: the pneumatic control system and timeclock/electric relay logic system. The pneumatic system was really used for large commercial and industrial buildings and the timeclock/electric relay logic systems were used in light commercial buildings. I installed timeclock/electric relay logic systems in banks, schools, office buildings and more. Both systems at the time were state of the art and both systems were less than perfect with inherent issues.

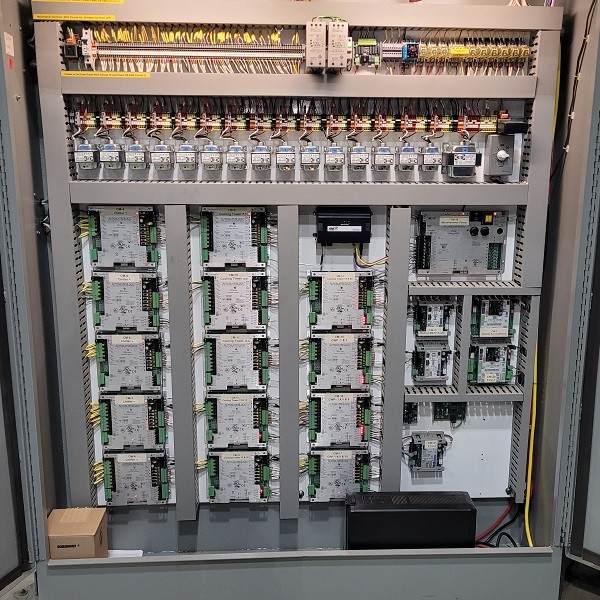

In the late 1970s and early 1980s, companies were developing and selling Direct Digital Control (DDC) energy management systems that were computer based. I remember reading about DDC systems and thinking how cool it was for computers to control HVAC equipment. I got to install my first DDC system in the early 90s – a Parker System in a commercial office building. The DDC control system was so powerful and much easier (and cheaper) to install compared to all previous systems. So DDC systems very quickly took over the control market. Pneumatic and timeclock/relay logic systems became a thing of the past just like that 8-track tape player.

The Evolution of DDC Energy Management Systems

The first DDC (EMS) systems all had an onsite terminal computer that usually resided in a dark corner in a mechanical room, and later we used a modem for remote access to the system. This was a huge innovation; remote communication with the system was unheard-of at this time. Not long after, unit graphics were added. It was a single-line illustration of the HVAC equipment with data from the equipment pasted over the graphic. Yes, these graphics were basic and not artistic, but at the time a big innovation and really forward thinking. For me, I was “wowed” the first time I saw the Automated Logic Supervision system with thermal graphics floorplans. This system, with its building floorplan layout with colors that represented the room temperature, completely blew me away. Since that time, it’s become an industry standard. Really, during this timeframe, each manufacturer developed innovative features that are still being used today and have spurred this industry forward. It was a great time to be a part of the industry… the defining-age of DDC systems.

Looking Ahead. What’s Next?

Over the last 20 years, the innovations in DDC systems innovations have been amazing. Noteworthy innovations include Web-based EMS Systems, Wireless Control Modules and Sensors, implementing BACnet protocols, and now IP base modules. I think the future will be full of new innovations. One feature I can see the industry leaning toward is Artificial Intelligence (AI) to predict maintenance, unit efficiency and service issues. Also, I think there will be more energy management features with real-time return on investment (ROI) built in. I expect that our DDC system will be asked to integrate and do more and more tasks like security/intruder detection, work order generation, and additional administrative tasks. Finally, I believe we will see significant development in air quality innovations – beyond how much fresh air is coming into the building. It will be more about what particles are in the air, and writing logic to control, dilute or destroy said particles.

I am sure of one thing after being in the controls industry for all these years. The building automation systems must change within the industry, or the industry will leave the systems behind.

Billy Blackburn, ACEM | Business Development Manager

A 30-year veteran of the HVAC and DDC Control Industry, Billy Blackburn, ACEM, is the Coastal Area Account/Business Development Manager for Harris Integrated Solutions.

He is a former factory certified centrifugal chiller technician and manager; is Allen Bradley PLC certified; and is a Network Plus and factory certified DDC control technician, trainer, and salesperson. Blackburn is based in Summerville, SC.

Billy Blackburn, ACEM | Business Development Manager

A 30-year veteran of the HVAC and DDC Control Industry, Billy Blackburn, ACEM, is the Coastal Area Account/Business Development Manager for Harris Integrated Solutions.

He is a former factory certified centrifugal chiller technician and manager; is Allen Bradley PLC certified; and is a Network Plus and factory certified DDC control technician, trainer, and salesperson. Blackburn is based in Summerville, SC.